In recent more than 10 years, science and technology are changing rapidly, and the demand for high-precision, fine and miniaturization of products is more urgent. At the same time, higher requirements for the development of dustless purification technology are put forward. Tens of thousands of dust free workshop in semiconductor, precision manufacturing, liquid crystal manufacturing, optical manufacturing, circuit board manufacturing and other industries are very common.

The purification of the indoor air is gradually diluted by the clean air flow, and the indoor pollution is gradually discharged to achieve the clean effect. Indoor air flow is a non parallel flow at uneven speed, mixed with reflux or vortex, and different grades of purification workshop is mainly achieved by different air volume in unit time.

Number: 100000 = 15; 10000 = 20; 1000 = 30; 100 = 500.

Pressure: the main workshop on the adjacent room is larger than 5Pa average wind speed: 10 level and 100 level 0.3 0.5m/s;

The temperature is more than 16 C in winter, and the temperature is less than 26 C in summer, and the fluctuation is + 2 C. Temperature 4565%;

The humidity of the GMP powder workshop is about 50%.

The humidity of the electronic workshop is slightly higher in order to avoid static electricity. The noise is less than or equal to 65dB (A);

The fresh air supply is 10% - 30% of the total air supply, and the illuminance 300LX.

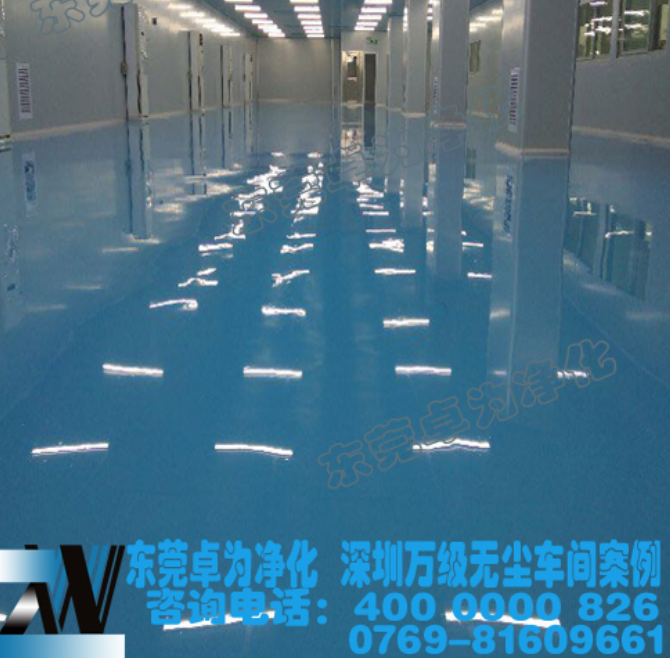

The following completion effect diagram: overall effect

Detail display section

Detail display part - Double blower shower

Detail display section - cargo shower

Ten years of focus, professional achievement!